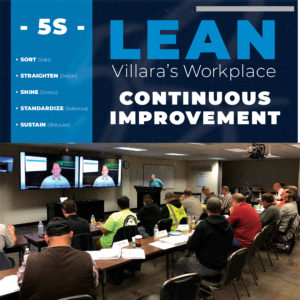

Lean is a method for creating a more effective business by eliminating wasteful practices and improving efficiency. The Lean process focuses on improving products and services based on what customers want and value. It’s a matter of Continuous Improvement. We at Villara believe that by having a more Lean workplace we save money, improve employee moral and bring superior products and services to the market. We have always been an industry leader…now we strive to be a Lean leader!

Lean is based around 5 key principles:

* There is also a 6th “S” which is called Safety. We take safety very seriously here and have a moto:

There are 10 “Commandments” to the Continuous Improvement process that help guide Lean thinking in the right direction. When we follow these, the transition to an improved workplace is simple!

1) Open your mind to change.

2) Think “yes” we can if…”.

3) Don’t attack people, attack problems.

4) Seek simple solutions

5) If it’s broken, stop to fix it.

6) Use creativity, not capital.

7) Problems are opportunities in disguise.

8) Find the root cause. Ask why, why, why, why, why.

9) Wisdom of many, not the knowledge of one.

10) There is no destination on the improvement journe

“Have you seen the wide-spread implementation of “4s” throughout the company? Trucks, bins, yards, warehouses, office spaces….almost everywhere you turn, we’re looking much neater, more organized, and overall just less “wasteful” looking. THANK YOU, THANK YOU, THANK YOU! We are well on the way to the full “Lean Transformation” that we’ve been studying and working towards, and I really believe that our financial success is affirming the value of ‘LEAN’.” – Rick Wylie, President

Available through the end of the year—but don’t wait! Submissions must be received early to qualify.

The federal tax credit for qualifying HVAC and Water Heater upgrades is available through the end of the year—but don’t wait! To ensure eligibility, your system must be installed and paperwork submitted before final processing deadlines.

Act now to lock in up to $2,000 in savings and enjoy quiet, efficient comfort all winter long.